With over the 120 years experiences in pump industry and as the first centrifugal pump manufacturer in Japan, the hydraulic design technology is the most remarkable competence of EBARA.

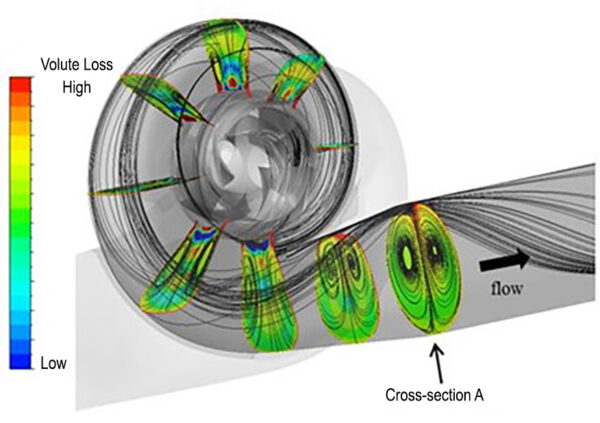

EBARA produces high-efficiency and high-performance pumps that meet the required operating conditions by using optimization technology combining the computational analysis of water flow inside the pump, and the unique design methodology of the internal geometry of pumps through simulations under prescribed ideal flow conditions (3D inverse design method). This unique design method has been applied to the extensive range of EBARA pumps to meet the customer duty points with the high level of pump efficiency and performance.

CFD(streamlines and total pressure loss in discharge volute)

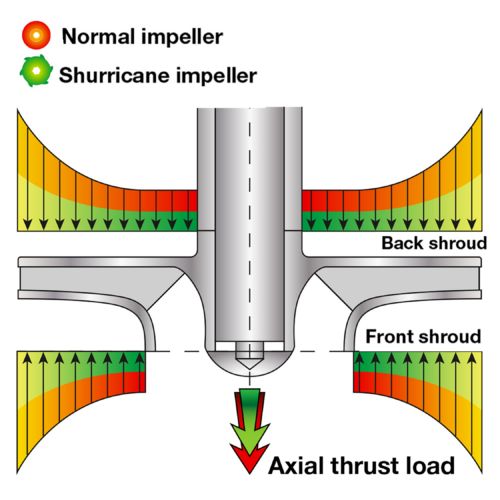

The pump axial thrust load is caused by the unbalance of the static pressure between a front shroud and a back shroud of an impeller. That always causes the reduction of the bearing life of the motor. The patented impeller design of EBARA, “SHURRICANETM” is applied to EBARA Vertical Multistage Pumps (EVMS Series) . SHURRICANETM maintains high efficiencies and very significantly reduces the axial thrust load meaning that any standard IEC motor can be used and bearing life is ensured.

SHURRICANETM

Impeller of EVMS Series

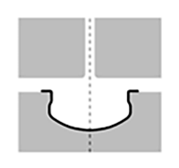

EBARA developed the unique production process of the pump casing: hydroforming. This innovative production method uses a high-pressure fluid (up to 1200 bar) to form the metal with perfectly smooth, highly flowing and without welding points. This innovative production method enables to obtain the one piece volute casing to obtain high pump efficiency and reliable quality. This unique design method has been applied to the extensive range of EBARA Stamped Stainless Steel Pumps such as 3 Series.

The steel disc is positioned in the press

The water is injected into the mold at a pressure of 1200 bar

The water fills the whole mold, thus deforming the steel disc

The press is raised and the pump body is formed without welding points

The Production process of the hydroformed volute casing

A hydroformed pump volute casing

EBARA pumps are manufactured to the highest standard of quality, and achieve reliable operating performance by means of rigorous technical evaluation criteria and control programs that involve the whole manufacturing process.

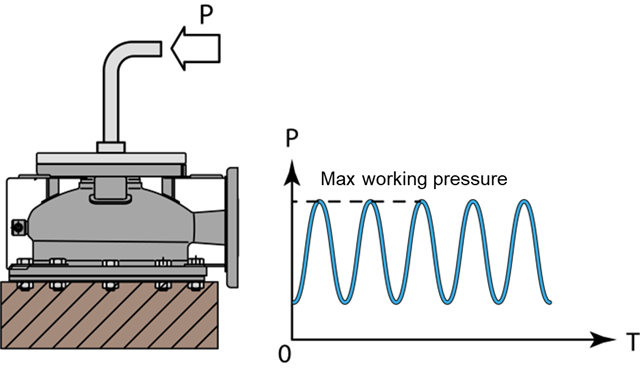

The endurance test with one million cycles of pressure pulsations is applied to the product development stage of EBARA pumps and ensure the highest reliability in the pump industries.

An example of the endurance test diagram